Building polymer-framed, Glock-style 9 mm semi-automatic pistols at home has been a popular pastime with shooting sports enthusiasts for quite some time. Components, kits and support gear sized for the compact Glock model G19 and its clones abound. This is because the G19 is among the most popular handguns yet devised. Although the next generation of smaller “micro nines” are designed to be more compact for easier daily carry, the G19 still offers a best-of-class balance of size, ammunition capacity and comfortable shooting characteristics.

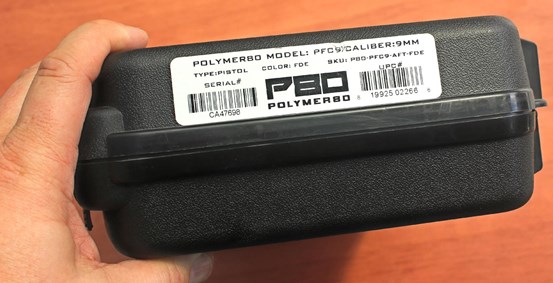

This 9 mm pistol kit arrives in a foam lined handgun case which can be used to store the gun once it's complete.

Getting started with an at-home pistol build project can look daunting for the first-time builder. What parts should you choose? How much should you spend? What amount of hands-on work do you want for a first-time project? As I was pursuing the G19 components field a while ago, I came across Polymer 80's (P80) series of AFT, or Assemble for Thyself, semi-automatic pistol kits. I put in a request for the number P80-PFC9-AFT-FDE kit which yields a compact version of the company's PF series polymer framed, striker fired 9 mm pistol with a flat dark earth frame. After assembling the gun for myself, here are six reasons why it's a great fit for a first time at-home build project:

All of the pistol's components are provided including one 15-round magazine.

1. Sweat Equity Saves Money

The top reason folks usually consider assembling firearms at home is to save money. The factory complete version of the P80 PF Series pistol lists for a suggested retail price of $599, which is comparable to a factory fresh Glock G19. The AFT kit for the same pistol model is listed for $499 with real world prices closer to (sometimes less than) $400. That's around a $200 savings for about an hour or so spent assembling the gun yourself. The money saved will come in handy for ammunition, holsters, spare magazines or shooting range fees.

The in-house custom slide arrives fully assembled with a factory installed steel sight set.

2. The Slide Arrives Fully Assembled

Although assembling a Gen 3 pattern slide is not particularly difficult, it does call for a few specialized tools including a rear sight setting tool ($150), a front sight nut driver ($45) and a striker channel liner tool ($35). Although folks who decide to pursue additional build projects are likely to invest in these tools down the road, P80 saves first time builders these tool costs by shipping the AFT kit's slide fully assembled. All of the parts are in place including the barrel and the recoil assembly.

The slide features in-house custom beveling at both ends, stylized cocking serrations and an aluminum end plate.

One of the things I appreciate about this kit is that P80 does not skimp on the slide's features. Both the slide and the barrel are made of stainless steel and treated with a durable matte black nitride finish. The in-house custom work includes unique bevels at the nose and rear of the slide, deep accent grooves on both sides along with stylized front and rear cocking serrations. The white dot front sight and the serrated rear sight have been upgraded from polymer to steel. The slide's end plate, which is usually made of polymer, has been replaced with an anodized aluminum plate.

The polymer frame's features include a 4-slot accessory rail, a generous trigger guard and aggressive grip texturing.

3. The Frame Arrives Ready to Use

Polymer 80 got its start by offering 80% pistol frame “blanks,” which are incomplete frames that require drilling and milling before they can be used. But the AFT kits do not ship with blanks. Instead, this build includes the same factory-finished and serial numbered frames the company uses for their complete PF pistols. This cuts down on tools and work time. But it should be noted here that a serial numbered pistol frame is considered a “firearm” by the federal government. This means the kit must be purchased through a licensed firearms dealer (FFL) with the same paperwork and fees as a handgun.

The frame is serial numbered and shipped ready to use. No milling or modifications are required.

The frame is sized to be compatible with most Glock G19 holsters along with familiar Gen 3 grip dimensions. But P80 has added several nice touches to the frame to help it stand out from the crowd. The dust cover features a 1.75" 4-slot Picatinny accessory rail. The oversize trigger guard is curved and shaped for improved comfort and the magazine release button is checkered for improved purchase. The grip has a more aggressive texturing on all four sides with a short beaver tail at the top and a lip at the front of the magazine well to protect the little finger from getting pinched during quick reloads. The kit arrives with one P80 15-round metal lined polymer magazine.

P80 makes their components in house and stamp's their logo everywhere possible to prove it.

4. All of the Components Are Provided

Some more experienced gun builders are thrilled to seek out every pin, spring and component that goes into an at-home project. For them, hunting through a broad selection of manufacturers and components is a part of why they enjoy the hobby.

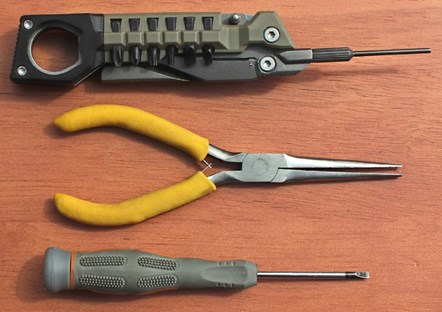

The author used a small pair of pliers and an eyeglass screwdriver in addition to the 3/32" pin punch to assemble the pistol.

But for rookies, trying to sift through seemingly infinite options can be daunting. P80 provides the small parts needed to flesh out the frame, including a complete flat-faced trigger group that provides a smoother than usual trigger pull. P80 makes their own small parts for these guns. This is hard to miss since they have applied their logo to every part with a flat surface that can be stamped or engraved.

Assembly begins with installing the slide release and the magazine release with the provided springs.

5. Super Simple Tool Set

Many parts simply snap together or drop into place in the frame. So technically speaking, the only tool required to flesh out the Glock-pattern pistol frame is a 3/32" pin punch for manipulating some of the springs and setting the frame pins. The punch I used this time around is a fold-out feature of the Real Avid Pistol Tool multi-tool (Top). But a factory standard Glock tool, or just about any 3/32" pin punch, will do the trick.

Next the locking block and rear rail module are pressed into place.

I like to include a jeweler's sized set of needle nose pliers (Center) and a standard blade eyeglass screwdriver (Bottom) in the tool set for installing the stick spring which supports the magazine release button. You can get by with just the punch. But if you have these two tools on hand they simplify the process. The pliers are used to set the spring in place inside the grip frame while the screwdriver makes it easier to lift and set the spring into the release button notch than the pin punch.

The trigger group needs to be fully assembled before it's placed in the frame.

6. Fairly Easy Assembly

How easy or hard a build project seems is a good deal like trying to describe levels of felt recoil. A seasoned revolver wrangler may find the recoil of a .44 Mag. perfectly manageable while the first round fired by a new shooter can feel like getting kicked in the hand by a Kentucky mule. So I won't pretend that I know where you're at in your learning to build process. That being said, the old saying holds true with Glock-type pistol assembly: it's (relatively) easy once you've seen it done.

The AFT kit arrives with a straightforward set of printed instructions with diagrams walking you through the process. Because the slide is fully assembled, the magazine arrives ready to use and the frame is finished at the factory, the work left to be done is to install about twenty small parts in the frame. The parts provided by P80 for this build were well made, proper sized and fit together neatly without any complications.

With the trigger group in place, the frame pins can be installed.

With a work space prepared, the parts sorted, tools on hand and at least one reading of the instructions complete, the build time should be between 30 minutes to an hour or so. The key is to not be in a big hurry to get the work done. Slow down, take your time, and reference the instructions or seek out online instructional videos as needed. Some steps are not universal, so don't expect videos for Glocks or other manufacturers to line up one hundred percent to the P80 build. This how-to article has some helpful photos and tips for installing the take down lever and magazine release button along with some of the steps for assembling the trigger group.

With all of the frame's internal components in place, and the frame pins set, the pistol is ready to be fully assembled.

With the pistol completely assembled, take a few minutes to run a set of bench checks. This means testing all of the gun's operations without any ammunition present to ensure the action and controls are operating properly. When it passes the bench checks, disassemble the pistol, lubricate it and put it back together. Now your freshly minted P80 pistol is ready to take to the shooting range.

Enjoy the pride that comes with owning and shooting a pistol you put together yourself.